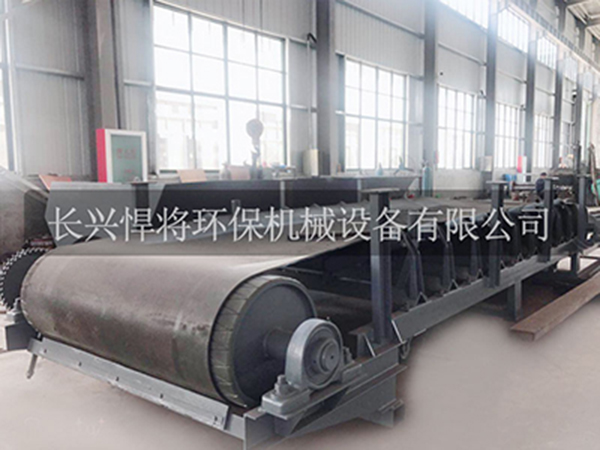

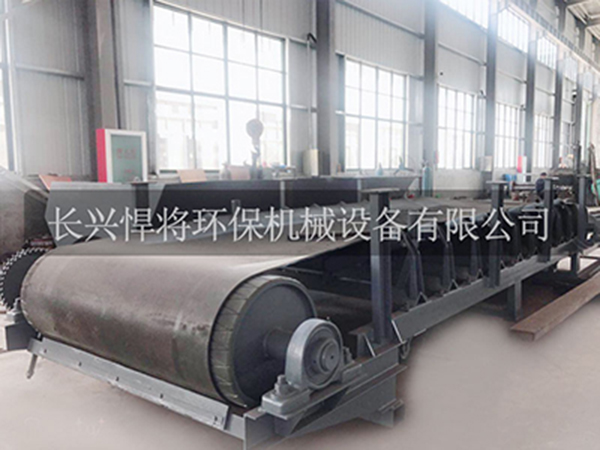

The belt conveyor is mainly composed of two end rollers a closed conveyor belt tightly sheathed on them. The drum that drives the conveyor belt to rotate is called driving drum (transmission drum); the other drum that only changes the movement direction of the conveyor belt is called steering drum. The driving roller is driven by the motor through the reducer, the conveyor belt is driven by the friction between the driving roller the conveyor belt. The driving roller is generally installed at the discharge end to increase the traction facilitate the drag. The material is fed by the feeding end, falls on the rotating conveyor belt, is transported to the discharge end for discharge by the friction of the conveyor belt.

Scope of application

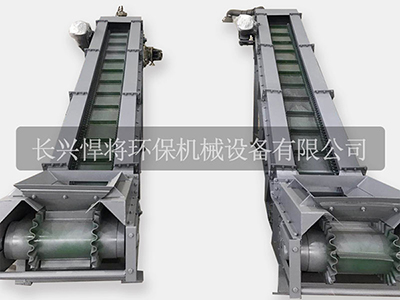

It can be used for horizontal transportation inclined transportation, it is very convenient to use. It is widely used in various modern industrial enterprises, such as underground roadway of mine, ground transportation system of mine, open pit concentrator. According to the requirements of the conveying process, it can be transported by a single machine, by multiple machines with other conveying equipment to form a horizontal inclined conveying system, so as to meet the needs of different layout forms of operation lines.

Characteristics advantages

The main feature of belt conveyor is that the fuselage can be easily retracted, with belt storage bin, the tail can be extended shortened with the advance of coal mining face, the structure is compact. It can be directly laid on the roadway floor without foundation. The frame is light convenient for disassembly assembly. When the conveying capacity distance are large, the intermediate driving device can be equipped to meet the requirements. According to the requirements of the conveying process, the material can be transported by single unit by multi unit combined with horizontal inclined conveying system.

Belt conveyor is widely used in metallurgy, coal, transportation, water electricity, chemical industry other departments, because it has the advantages of large conveying capacity, simple structure, convenient maintenance, low cost, strong versatility so on.

The belt conveyor runs reliably. Belt conveyors are used in many important production units that need continuous operation, such as coal conveying in power plants, bulk material conveying in steel cement plants, ship loading unloading in ports. If it is shut down in these occasions, the loss is huge. If necessary, the belt conveyor can work continuously one by one.

Low power consumption of belt conveyor. Because there is almost no relative movement between the material the conveyor belt, only the running resistance is small (about 1 / 3-1 / 5 of the scraper conveyor), but also the abrasion crushing of the cargo load are small, the productivity is high. All these are beneficial to reduce the production cost.

The belt conveyor has strong adaptability flexibility. The length of the line depends on the demand. The length can be as short as a few meters, the length can reach more than 10km. It can be installed in a small tunnel, it can be set up above the ground traffic chaos dangerous areas.

According to the requirements of the technological process, the belt conveyor can receive materials one more points flexibly, can also discharge materials to multiple points several sections. When the material is fed to the conveyor belt at several points at the same time (such as the conveyor under the coal bunker of the coal preparation plant) through the uniform feeding equipment at any point along the length direction of the belt conveyor, the belt conveyor becomes a main conveying trunk line.

The belt conveyor can take materials the roadway under the material pile of the coal storage yard, can mix different materials of each pile when necessary. The material can be simply discharged the head of the conveyor, discharged at any point along the length of the conveyor belt by plough discharger mobile discharger.