The sealing of screw conveyor equipment is very important for screw conveyor. should we start to specify the seals? The editor of the screw conveyor manufacturer will conduct the analysis for everyone.

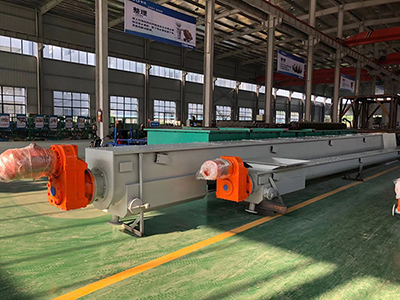

If the appearance of screw conveyor is different, it can be roughly divided into U-shaped tubular. The sealing performance of U-type screw conveyor is worse than that of tubular screw conveyor.

If conveying powdery materials, it is recommended to use round tube screw conveyor, granular materials can use U-shaped screw conveyor; if there is pressure inside, it needs to be explained in advance, the processing needs to be customized by the manufacturer!

The machine body of tubular screw conveyor directly adopts round steel pipe, so the sealing performance is better; the cover plate of U-shaped screw conveyor is tiled clamped on the shell with cover plate buckle, in order to improve the sealing performance, the user can make the canvas between the cover plate the shell thicker. The two types of screw conveyor have their own advantages disadvantages. The equipment of U-type screw conveyor is as good as tube type, but its structure is convenient for users to clean. The accumulated material is easy to observe, inspect maintain.

Screw conveyor equipment for powder material conveying is relatively common. Screw conveyor should only ensure continuous stable material conveying, but also meet the corresponding requirements of conveying speed, materials should be scattered in the conveying process.

In order to meet the above requirements, on the basis of fully considering the characteristics of powder materials, the tightness of screw conveyor is a more important problem: that is to say, if the shaft bearing seat of screw conveyor equipment are well sealed, the fine powder shaft often leaks into the bearing seat, causing bearing damage, frequent maintenance affecting the stable operation of the equipment; Therefore, trying to solve the bearing sealing problem of screw conveyor equipment is the key to reduce the maintenance workload improve the stable operation efficiency of screw conveyor equipment.

The specific methods to improve the screw conveyor equipment are as follows:

1. Extend the size of the bushing at the end seat sealing packing, increase the number of packing rings, improve the sealing effect;

2. The oil cup is used for lubrication, the contact surface between the shaft the packing the packing itself are filled with oil through the oil cup, so as to enhance the lubrication penetration effect, reduce the wear of the packing the shaft, form an oil film layer at the same time, so as to prevent the powder flowing out the clearance of the journal, the oil groove extends to the inner layer, which has obvious sealing effect;

3. A pair of labyrinth skeleton seal rings are designed on the inner side of the end seat bushing. One labyrinth seal ring is fixed on the end seat bushing, the other is installed on the shaft runs with the shaft to prevent the material powder flowing out scattering. Play a sealing role.

The seal configuration of screw conveyor equipment is different according to the material needs. Material properties can also affect the sealing of equipment. Therefore, the design needs to adapt to local conditions, reasonable design can make the screw conveyor equipment run normally.

Screw conveyor equipment plays an important role in the current production of enterprises. However, the sealing part of the equipment has always been a problem faced by screw conveyor equipment manufacturers. If the seal is tight in the production process, the material is likely to leak the gap. The production environment of the workshop is damaged, so the dense sealing performance of the screw conveyor is the key to the success of the equipment. The sealing performance of screw conveyor is good the leakage is serious. The powder pile on the floor of the workshop will seriously affect the production environment of the enterprise; here, we will cause the tightness of the seal improve it.